In more and more areas of everyday dental work, the path leads to the digital laboratory. To ensure greater flexibility and more efficient workflows at the end of this path, we offer the digital workflow – qualified by Dreve. All process steps of the dental 3D workflow are seamlessly integrated and ensure consistently high quality.

You achieve precise print results in series with a complete system in which all process components are seamlessly integrated. The Dreve 3D printing product portfolio is based on the system concept: devices and materials, software and hardware are optimally matched and adjusted to each other. This results in a validated process chain with printed products that are more precise and last longer.

Phrozen Sonic CS+ – Qualified by Dreve Compact LCD desktop printer with 22 μm resolution and an innovative 385 nm LED light source, delivering high light intensity for fast build times.

The high-quality full-metal housing and improved vat and platform handling make the Phrozen Sonic CS+ a user-friendly 3D printer for all dental applications.

Light-curing resin for the fabrication of dental drill guides.

Guides made from FotoDent® guide are dimensionally stable and biocompatible.

| Color | blue transparent |

| Flexural modulus | > 1.700 MPa |

| Flexular strength | ≥ 75 MPa |

| Elongation at break | > 10–15 % |

| Final hardness | > 80–85 Shore D |

| Size | 1 kg bottle |

| Print speed (mm/h) | 20.5 |

| Print time/platform (min) | 146 |

| Print time/part (min) | 9.1 |

| Parts/platform vert. | 16 |

| Material consumption (g/part) | 5 |

| Absolute height (mm) | 50 |

| Cost/part ($/part) | 2.08 |

| 385 nm | D35650 |

| 405 nm | D35600 |

Light-curing resin for the fabrication of transparent, orthodontic transfer trays.

Verification of correct bracket positions possible at any time – before and after bonding. Optimum flexibility for easy removal. Can be used with all common bracket systems.

| Final hardness | 90 Shore A |

| Color | clear transparent |

| Viscosity | 0.7 ± 0.2 Pa s |

| Tensile elongation | ≥ 45 % |

| Print speed (mm/h) | 12.4 |

| Print time/platform (min) | 48 |

| Print time/part (min) | 4.8 |

| Parts/platform hor. | 10 |

| Material consumption (g/part) | 6 |

| Absolute height (mm) | 10 |

| Cost/part ($/part) | 2.08 |

D35120

Light-curing resin for the fabrication of transparent, orthodontic transfer trays.

The material is highly compatible: It can be used with all commercially available embedding materials.

| Color | red transparent |

| Final hardness | 80–90 Shore D |

| Flexural modulus | ≥ 2,000 MPa |

| Flexular strength | ≥ 100 MPa |

| Size | 1 kg bottle |

| Viscosity | < 0.3 Pa s |

| Elongation at break | 7.5 %–11 % |

| Print speed (mm/h) | 23.1 |

| Print time/platform (min) | 91 |

| Print time/part (min) | 7.6 |

| Parts/platform hor. | 12 |

| Material consumption (g/part) | 5 |

| Absolute height (mm) | 35 |

| Cost/part (in $/part) | 1.92 |

D35100

Light-curing resin for the production of dental prosthetic bases.

The use of the resin enables accurate results with the greatest possible dimensional stability. FotoDent® denture is free of MMA and color stable.

| Final hardness | 80 Shore D |

| Flexural modulus | > 2,000 MPa |

| Flexular strength | > 80 MPa |

| Size | 1 kg bottle |

| Viscosity | 0.4–0.6 Pa s |

| Print speed (mm/h) | 24.2 |

| Print time/platform (min) | 136 |

| Print time/part (min) | 9.1 |

| Parts/platform vert. | 15 |

| Material consumption (g/part) | 15 |

| Absolute height (mm) | 55 |

| Cost/part (in $/part) | 6.70 |

| pink transparent | D35500 |

| pink opaque | D35501 |

Optimized, biocompatible resin for the fabrication of dental, individual impression trays.

High reactivity with low viscosity. Simplified cleaning and improved mechanical properties. Two times faster printing times, layer thicknesses of 300 μm possible. The finished impression trays have a homogeneous surface, which significantly reduces manual reworking.

| Flexural modulus | ≥ 2,100 MPa |

| Flexular strength | > 90 MPa |

| Size | 1 kg bottle |

| Viscosity | approx. 1.2 Pa s |

| Print speed (mm/h) | 46.4 |

| Print time/platform (min) | 90 |

| Print time/part (min) | 5.6 |

| Parts/platform vert. | 16 |

| Material consumption (g/part) | 15 |

| Absolute height (mm) | 70 |

| Cost/part ($/part) | 3.40 |

| Print speed (mm/h) | 51 |

| Print time/platform (min) | 82 |

| Print time/part (min) | 5.1 |

| Parts/platform vert. | 16 |

| Material consumption (g/part) | 15 |

| Absolute height (mm) | 70 |

| Cost/part ($/part) | 3.40 |

| Print speed (mm/h) | 48.5 |

| Print time/platform (min) | 86.5 |

| Print time/part (min) | 5.4 |

| Parts/platform vert. | 16 |

| Material consumption (g/part) | 15 |

| Absolute height (mm) | 70 |

| Cost/part ($/part) | 3.40 |

| blue transparent | D353001 |

| green transparent | D353002 |

| reddish transparent | D353003 |

Light-curing resin for the fabrication of dental gingival masks.

Permanently soft and flexible. Perfect combinable with the working models made of FotoDent® biobased model and model2 resins.

| Final hardness | approx. 70 Shore A |

| Color | pink |

| Size | 1 kg bottle |

| Recovery after deformation | 100 % |

| Viscosity | approx. 2 Pa s |

| Bending strain | > 40 % |

| Print speed (mm/h) | 16.4 |

| Print time/platform (min) | 70 |

| Print time/part (min) | 1.3 |

| Parts/platform hor. | 55 |

| Material consumption (g/part) | 2 |

| Absolute height (mm) | 19 |

| Cost/part ($/part) | 0.68 |

D35850

Light-curing resin that consists of 50 % renewable raw materials.

The material properties are optimally for model production (also in the aligner workflow). The material can be cleaned with FotoClean.

| Color | beige opaque |

| Size | 1 kg bottle |

| Flexural modulus | ≥ 2,200 MPa |

| Viscosity | ~ 0.6 Pa s |

| Flexular strength | ≥ 95 MPa |

| Print speed (mm/h) | 20.7 |

| Print time/platform (min) | 38 |

| Print time/part (min) | 3.8 |

| Parts/platform hor. | 10 |

| Material consumption (g/part) | 12 |

| Absolute height (mm) | 13 |

| Cost/part ($/part) | 2.64 |

D35450

Light-curing resin for the fabrication of dental working models for orthodontics and prosthetics.

Faster printing process due to higher output with the accustomed detail precision. Also suitable for printing any expert and show models.

Please note: Depending on the selected color, the printing times of the models may differ.

| Final hardness | 80–86 Shore D |

| Flexural modulus | ≥ 1,900 MPa |

| Flexular strength | ≥ 85 MPa |

| Size | 1 kg bottle |

| Viscosity | 0.8–1.2 Pa s |

| Elongation at break | ≥ 8 % |

| Print speed (mm/h) | 24.6 |

| Print time/platform (min) | 32 |

| Print time/part (min) | 3.2 |

| Parts/platform hor. | 10 |

| Material consumption (g/part) | 12 |

| Absolute height (mm) | 13 |

| Cost/part ($/part) | 2.32 |

| Print speed (mm/h) | 20.7 |

| Print time/platform (min) | 38 |

| Print time/part (min) | 3.8 |

| Parts/platform hor. | 10 |

| Material consumption (g/part) | 12 |

| Absolute height (mm) | 13 |

| Cost/part ($/part) | 2.32 |

| Print speed (mm/h) | 27.3 |

| Print time/platform (min) | 29 |

| Print time/part (min) | 2.9 |

| Parts/platform hor. | 10 |

| Material consumption (g/part) | 12 |

| Absolute height (mm) | 13 |

| Cost/part ($/part) | 2.32 |

| beige opaque | D354002 |

| black | D354003 |

| white | D354004 |

Biobased insulating agent for 3D printed resin models in the processing of autopolymers.

Optimum insulation between the resin dental model and the resin plate for the scattering process in the orthodontic field. Also suitable for the fabrication of dentures, e.g. from Castdon.

| Size | 100 ml |

D4307

Cleaning unit for 3D printed parts after the print process.

Device with magnetic stir technology and automatic transfer between the two cleaning containers. Various cleaning programs can be selected and set via touchscreen. The platform of the Sonic CS+ can be directly hooked into the device and cleaned together with the attached parts.

| Dimensions (H x W x D) | 600 x 570 x 400 mm |

| Color | red |

| Weight | 15 kg |

| Voltage | 100–240 V / 50–60 Hz, 0.7 A |

D3600

FotoClean is a ready-to-use, water-based cleaning mixture for use in the heated ultrasonic cleaning device Bandelin for cleaning additively manufactured components.

| 2x 1l bottle | D4397 |

| 5l canister | D4398 |

Laboratory device based on LED technology for curing 3D printed parts.

Ensures mechanical properties and biocompatibility through effective depth curing. The PCU vario 160 offers both, the option of a vacuum atmosphere and the possibility of curing under nitrogen. Biocompatible curing without an inhibition layer can be ensured.

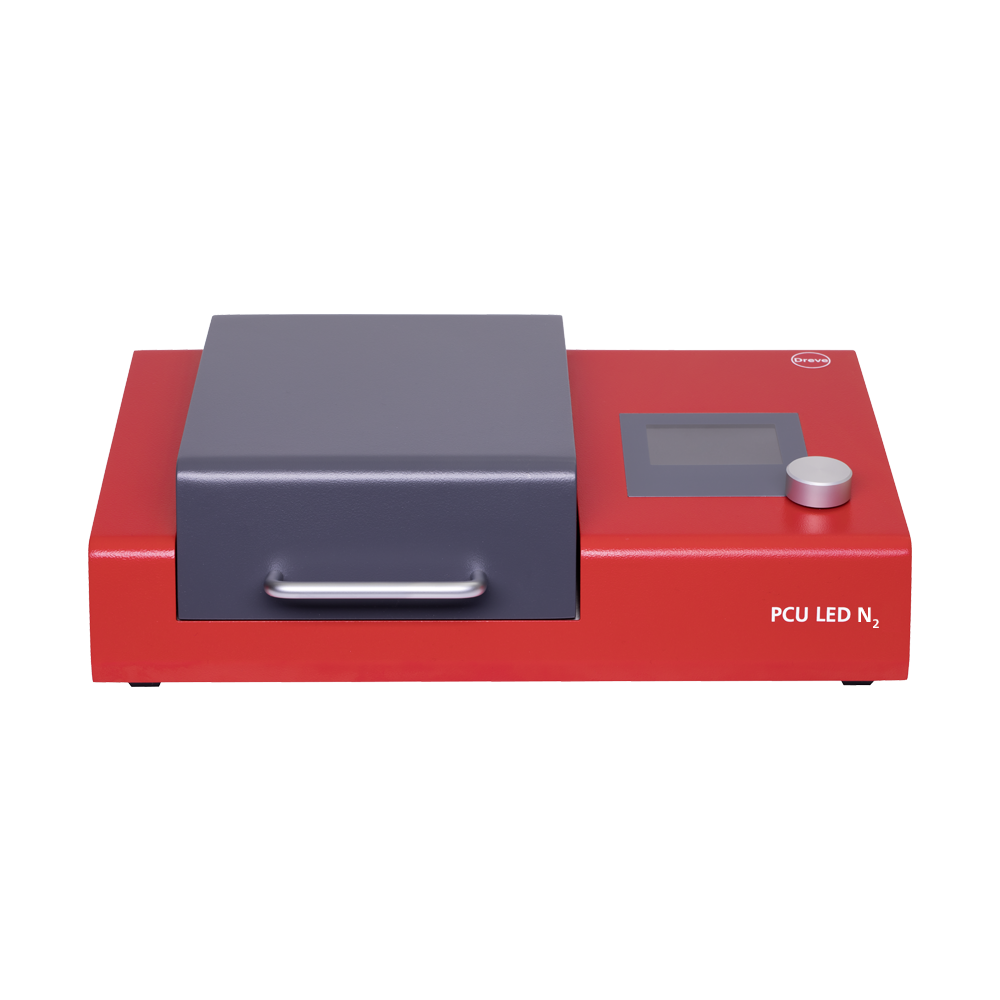

Laboratory unit on LED-basis for the curing of 3D printed parts.

Ensuring of mechanics and biocompatibility through effective deep curing. Two different curing enviroments selectable depending on the application area. The additionally eligible nitrogen enviroment of PCU LED N2 ensures cured components without inhibition layer – for laboratory and medical devices.

| Color | red |

| Dimensions (H x W x D) | 110 x 389 x 276 |

| Weight | 9.3 kg |

| Voltage | 100–240 V / 50–60 Hz, 150 W |

4317

| Printer | Model | denture | splint | IBT | guide | tray2 | cast | model2 beige | model2 black | model2 white | gingiva | biobased model |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Phrozen | Sonic XL 4K (2022) "qualified by Dreve" | • | • | • | • | • | • | • | • | • | • | • |

| Ackuretta | SOL | o | o | • | o | o | • | o | • | o | o | |

| ASIGA | MAX UV | • | • | • | • | • | • | • | • | • | • | |

| PRO 4K | • | • | • | • | • | • | • | • | • | • | ||

| atum 3D | DLP-STATION 5-405 | • | ||||||||||

| Carbon | M1 | • | • | • | ||||||||

| M2 | • | • | • | • | ||||||||

| M3 | • | • | • | • | ||||||||

| M3 Max | • | • | • | • | ||||||||

| Dekema | trix print2 | • | • | |||||||||

| LuxCreo | iLux Pro Dental | o | o | o | o | o | o | |||||

| Microlay | EVE | o | • | |||||||||

| VERSUS | o | • | ||||||||||

| MiiCraft | 125 | • | • | • | • | • | • | • | ||||

| Photocentric | Liquid Crystal OPUS | o | o | o | o | |||||||

| rapidshape | D series | • | • | • | • | • | • | • | • | • | • | |

| DII series | • | • | • | • | • | • | • | • | • | • | ||

| D20+/D30+ | • | • | • | • | • | • | • | • | • | • | ||

| D90II | • | |||||||||||

| Shining3D | AccuFab-L4D | o | o | o | o | o | o | o | o | o | o | |

| Stratasys | Origin One | • | ||||||||||

| W2P | SolFlex 350 | • | ||||||||||

| SolFlex 650 | • |

• Print parameter available

o Print parameter available soon