Our specially matching working materials and the large selection of Biopor® AB silicones, Fotoplast® acrylates and lacquers facilitate the daily working procession the production of individual and precisely fitting earmolds in the manual process. Our biocompatible materials are characterized by easy processing and fast polymerization.

When 2 become 1: We have successfully combined the advantages of Biopor® AB Xtreme with those of Biopor® AB. Hence, this silicone offers you the best features of both products.

Major advantages are that you save valuable time and effort when processing the material, as curing time is reduced to 15 minutes and postcuring is possible at room temperature! In addition, the colors are brighter and even more intense. The new Biopor® AB is still available in the usual final hardnesses – 25, 40, 60 Shore A.

| Material | Biopor® AB 25 Shore A | Biopor® AB 40 Shore A | Biopor® AB 60 Shore A | Biopor® AB Xtrack 40 Shore A | Biopor® AB light 25 Shore A | Biopor® fluoreszent 40 Shore A |

|---|---|---|---|---|---|---|

| transparent | ||||||

| clear transparent | 28351 | 28200 | 28400 | |||

| reddish transparent | 28301 | 28201 | 28401 | 28501 | ||

| red transparent | 28311 | 28207 | ||||

| blue transparent | 28321 | 28290 | 284121 | |||

| yellow transparent | 28331 | |||||

| green transparent | 28361 | |||||

| emerald green transparent | 28120 | |||||

| purple transparent | 28208 | |||||

| pink transparent | 28209 | |||||

| light brown transparent | 28293 | 28439 | ||||

| medium brown transparent | 28292 | 28492 | ||||

| opaque | ||||||

| red opaque | 28312 | 28212 | 28412 | |||

| blue opaque | 28322 | 28222 | 28422 | 29040 | ||

| yellow opaque | 28332 | 28232 | 28432 | |||

| white opaque | 28362 | 28262 | 28462 | 28562 | ||

| orange opaque | 28303 | 28203 | 28434 | |||

| green opaque | 28242 | 28442 | ||||

| black opaque | 28252 | 28452 | 28552 | |||

| beige opaque | 28272 | 28472 | 28571 | |||

| purple opaque | 28202 | 28416 | 28516 | |||

| pink opaque | 28204 | |||||

| neon yellow opaque | 28214 | 28527 | ||||

| neon green opaque | 28215 | 28543 | ||||

| neon pink opaque | 28216 | 28513 | ||||

| neon orange opaque | 28217 | 28593 | ||||

| fuchsia magenta opaque | 28415 | |||||

| azure blue opaque | 28423 | |||||

| light blue opaque | 28524 | |||||

| dark blue opaque | 28525 | |||||

| dark red opaque | 28526 | |||||

| metallic | ||||||

| turquoise metallic | 28101 | |||||

| silver metallic | 28105 | |||||

| blue metallic | 28106 | |||||

| red metallic | 28108 | |||||

| pink metallic | 28109 | |||||

| black metallic | 28113 | |||||

| champagne metallic | 28114 | |||||

| silver transparent metallic | 28117 | |||||

| smoky grey metallic | 28124 | |||||

| fluorescent | ||||||

| yellow fluorescent | 28700 | |||||

| green fluorescent | 28351 | 28200 | 28400 | 28701 | ||

| blue fluorescent | 28351 | 28200 | 28400 | 28702 | ||

| magenta fluorescent | 28351 | 28200 | 28400 | 28703 | ||

| red fluorescent | 28351 | 28200 | 28400 | 28704 | ||

| orange fluorescent | 28351 | 28200 | 28400 | 28705 |

Pressure polymerization unit with a temperature range up to 95 °C (203 °F) for one brass flask including clamp or four large rubber embedding molds (0.50 mm).

3429 (230 V – 50/60 Hz)

3429A (115 V – 50/60 Hz)

Pressure polymerization unit with a temperature range up to 95 °C (203 °F), with infinitely variable pressure from 3 to 6 bar. Thanks to the big volume of the pressure pot a high quantity of earmolds can be polymerized.

3423 (230 V – 50/60 Hz)

3423A (115 V – 50/60 Hz)

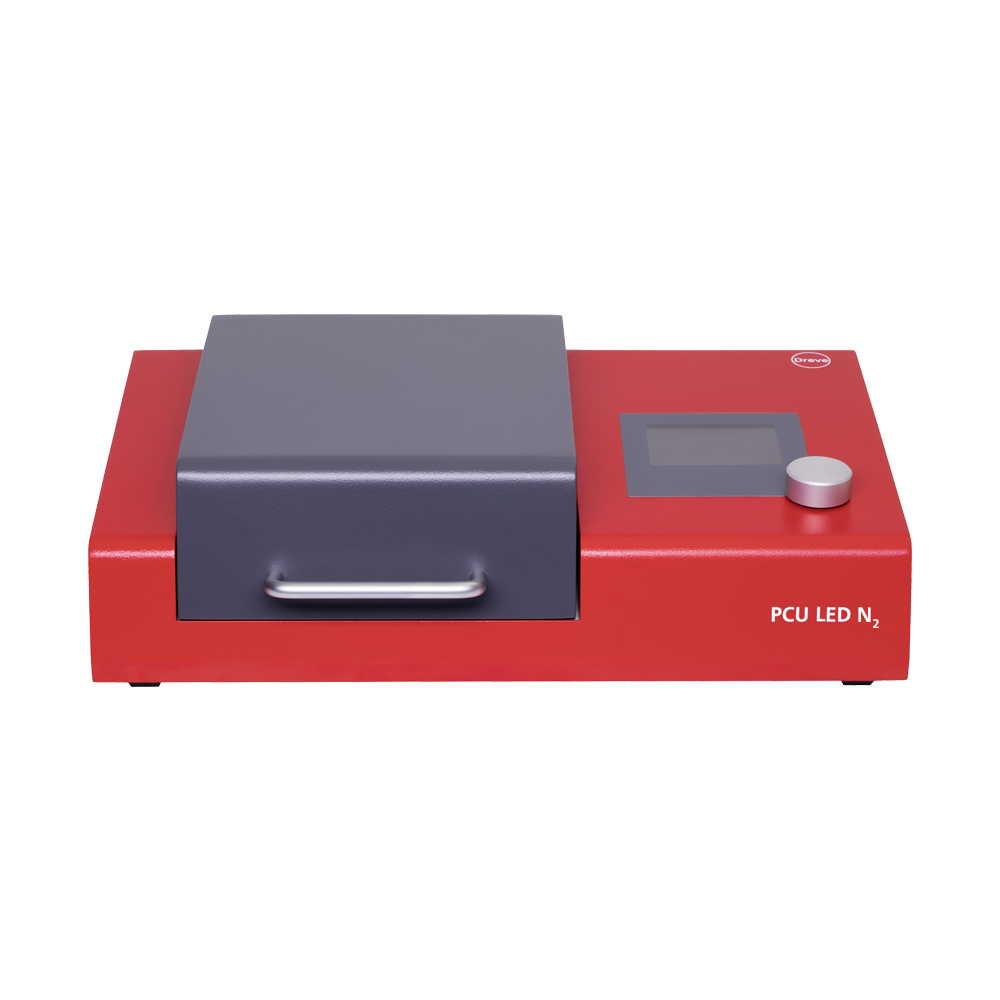

PCU LED N2 is the post-curing unit for safe manufacturing of 3D printed medical devices. Thanks to the option of post-curing in a nitrogen atmosphere, the PCU LED N2 is ideal for the production of earmolds, RICs and shells without inhibition layers. The software concept guarantees the user a simple operation and with the LED quick test an immediate check of the LED functionality. The administrator can define programs and read protocols. Further, they can calibrate and update the system.

4317

The Polylux 100 is a basic light polymerization unit for repairings and lacquerings. The unit is equipped with a UVA light source and mirrored internal inner surfaces, which ensure safe polymerization.

405

This compact unit is made up of a robust, powder-coated metal housing and a large, practical lid. The polymerization chamber is completely mirrored so a turning motor is not necessary for curing of coatings. The polymerization chamber provides space for four negative molds for earmolds with clamping tweezers. Additional safety is provided by the timer, which can be used to limit the maximum polymerization time to 5 or 10 min. The Polylux 500 enables the polymerization of resins and lacquers from our Fotoplast® range.

403