Discover the Future of 3D Printing: The Revolutionary Phrozen CS+ 3D Printer

Qualified by Dreve: For manufacturing earmolds and shells in great colors and brilliant transparency. Step into a new era of digital manufacturing in hearing acoustics with our groundbreaking 3D printer, perfect for sophisticated earmold designs. Pioneering 3D Printing. Innovation aus Tradition.

| Dimensions (H x W x D) | 550 x 380 x 360 mm |

| Layer thickness | 0.01–0.30 mm |

| Weight | approx. 20 kg |

| Voltage | 100-240 V / 50-60 Hz, 0.7 A |

D4700

Laboratory device on LED basis for curing 3D printed components. Ensuring mechanics and biocompatibility through effective deep curing. The PCU vario offers both the option of a vacuum atmosphere and the option of curing under nitrogen. Biocompatible curing without an inhibition layer can be ensured.

| Type | Licht polymerization unit |

| Powe | 1000 W |

| Weight | 45 kg |

| LED-wave length | 405 nm |

| Light intensity | max. 100 mW/cm2 per side |

| Curing chamber vol. (H x W x D) | 120 x 480 x 290 mm3 |

| Usable vol. (H x W x D) | 80 x 420 x 270 mm3 |

| Dimensions of device (H x W x D) | 240 x 660 x 383 mm3 |

| Environment while curing | Nitrogen, Ambient air, Vacuum |

4319

The unit features a magnetic stirrer technology and automatic transfer between the two Wash Buckets. Various cleaning programs can be selected and created via touchscreen. The platform of the Sonic XL 4K can be hooked directly into the unit and cleaned together with the adhering components.

| Dimensions (H x W x D) | 810 x 480 x 430 mm³ |

| Color | red |

| Weight | 16.5 kg |

| Voltage | 100–240 V / 50–60 Hz, 1.5 A |

D3600

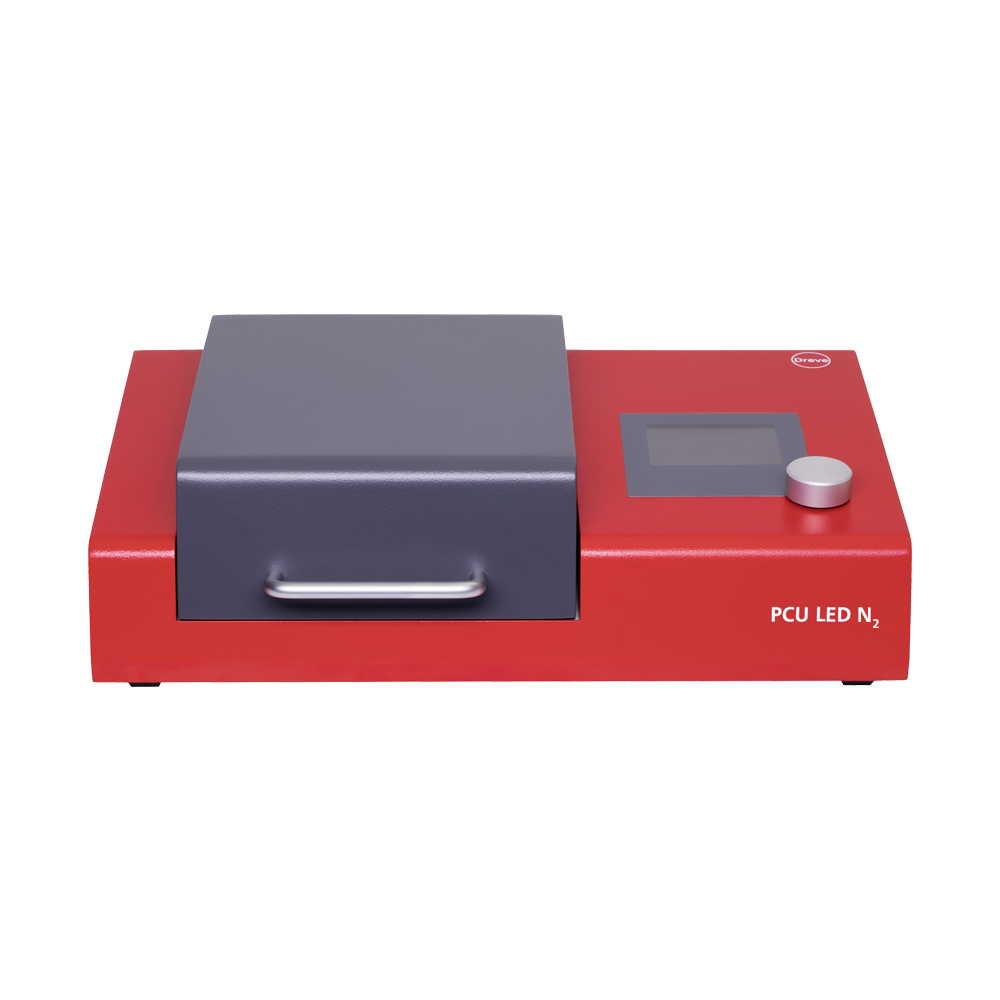

PCU LED N2 is the post-curing unit for safe manufacturing of 3D printed medical devices. Thanks to the option of post-curing in a nitrogen atmosphere, the PCU LED N2 is ideal for the production of earmolds, RICs and shells without inhibition layers. The software concept guarantees the user a simple operation and with the LED quick test an immediate check of the LED functionality. The administrator can define programs and read protocols. Further, they can calibrate and update the system.

4317